König & Meyer among the world market leaders – Wertheim ranked 7th in Germany

König & Meyer is proud to count itself among Germany’s global market leaders, thereby making a major contribution to the strong economic profile of the Wertheim region.

This is confirmed by the latest edition of the renowned “Lexikon der deutschen Weltmarktführer” (Encyclopedia of German World Market Leaders) in which Wertheim is ranked among the top 10 cities with the most global market leaders in Germany — alongside major cities such as Munich, Hamburg, and Berlin.

With the companies listed in the encyclopedia, Wertheim ranks seventh nationwide — surpassing even much larger cities such as Heilbronn and Stuttgart. Noteworthy: Relative to its population size, Wertheim holds a leading position — no other city of this size brings together so many global market leaders in one place.

König & Meyer is also part of this success and is grateful for the “World Market Leader 2025” seal, which was recently awarded to 12 companies in the city at Wertheim Castle.

For over 75 years, König & Meyer has stood for high-quality accessories for musical instruments and is known for innovative solutions, superior quality, and long-lasting craftsmanship. From music and instrument stands to microphone and speaker stands to multimedia gear, we provide sturdy and reliable equipment for musicians, studios, and live stages. With its refined design and precise manufacturing “Made in Germany,” König & Meyer remains the top choice for premium music accessories.

The award as a global market leader confirms our commitment to quality, innovation, and sustainable growth.

We are delighted to be working alongside many other strong companies to contribute to the economic strength of the region and make our location visible internationally.

MI industry will meet in Berlin at the SOMM DEALER DAYS

On October 29 and 30, the SOMM Dealer Days will take place in Berlin at the Estrel Congress Hotel. About 30 international exhibitors will present their products and services during the two days of the trade show.

We from König & Meyer will show you at our booth in Estrel Hall A booth number 29 especially our new products from 2021 and 2022.

In addition to the trade show exhibition, the pure B2B event will be accompanied by a congress with exclusive keynote speeches and information (MIBKON) specially designed for industry participants, as well as a first-class evening event with a gala dinner for all exhibiting companies, trade visitors and guests.

We look forward to seeing our customers again in Berlin and to the personal exchange that has been so lacking in the last 3 years! If you would like to arrange a meeting, please send us your appointment proposal by mail.

Besides König & Meyer the following companies will be present (in alphabetical order) : AUDIOWERK e. Kfm, Casio Europe GmbH, Conrad Mollenhauer GmbH, Cordial GmbH Sound & Audio Equipment, DAS Audio GmbH, FACE bvba, GEWA music GmbH, Hal Leonard Europe BV, inMusic Gmbh, KAWAI Europa GmbH, Lakewood Guitars GmbH & Co. KG, Mega Audio Gesellschaft für professionelle Audiotechnik mbH, Migma eG, Miyazawa Flutes Europe GmbH, MUSIK MEYER GmbH, Pearl Music Europe BV, Pro Arte Fine Acoustics GmbH, Reinhardt GmbH, Roland Meinl Musikinstrumente GmbH & Co. KG, SCHOTT MUSIC GmbH & Co. KG, Shure Europe GmbH, Sound Service Musikanlagen-Vertriebsgesellschaft mbH, Trius GmbH & Co. KG, Voggenreiter Verlag GmbH, Yamaha Music Europe GmbH

Further information to the industry event under: www.somm-dealer-days.eu

Address event location: ESTREL BERLIN | SONNENALLEE 225 | 12057 BERLIN

An award-winning company:

König & Meyer receives innovation award with TOP 100 seal

König & Meyer GmbH & Co. KG, based in Wertheim, has received the TOP 100 seal for 2021. This award honors particularly highly innovative medium-sized companies from all over Germany. Previously, the music accessories manufacturer had proven its innovative strength in a scientific selection process.

For more than 25 years, the “TOP 100” seal has been awarded to mid-sized companies based in Germany in recognition of outstanding innovation management. Every year, one hundred innovative companies across three size categories receive the award. In this way, “hidden champions” are bundled together on a single platform across all industries, which enables them to gain considerable visibility. As mentor, science journalist Ranga Yogeshwar gives this only competition of its kind a well-known face.

Companies are evaluated based on 120 criteria in five categories: Successful Innovations, Climate of Innovation, Innovative Processes/Organization, Benchmarking/Open Innovation, and Innovation-friendly Senior Management. The basic question is whether innovation is the product of deliberate planning and action or of chance alone, meaning whether innovative achievements can be repeated. The competition also looks at whether the solutions involved succeed on the market, and if so, how. This time around, special attention was paid to how companies responded to the COVID-19 pandemic.

Especially in these kinds of crisis situations, it is even clearer what innovative drive can achieve. With all cultural life in lockdown, demand for event technology and music equipment plunged. In response, König & Meyer sought out new opportunities. Within just three weeks, the company came up with a whole new product line and launched various disinfectant stands on the market.

CEO Gabriela König

“Our philosophy of streamlined communications, our own high level of vertical integration, and the structured processes we use for product development really proved their value here. The strong demand for these products helped us all through 2020 to absorb the sharp drop in sales that we saw particularly in terms of products for events, especially live events. The disinfectant stand product range has now grown to more than 30 products,” says CEO Gabriela König, describing the company’s internal flexibility.

The company also received special recognition for its structured approach to innovation management and the good innovation climate within the organization.

CTO Heiko Wolz

“We have a clear approach that ensures that the necessary steps from the idea to market launch don’t have to be reconsidered every time, thanks to defined project management. Our portfolio is balanced and encompasses everything from short-term to long-term projects. Advances in product development are monitored and coordinated regularly. Every new product is reviewed and tested before it is launched on the market. We have innovation project teams composed of employees from various areas, who are continuously in touch, sharing information and ideas. Streamlined communications and flat hierarchies give us agility in implementing projects,” says CTO Heiko Wolz, offering insight into the company’s internal processes.

Everything comes together

At König & Meyer, expertise and creativity come together. The company has its own design and development department with seven employees and dedicated product managers who interface with the management and the technical departments and with the sales and marketing teams. Product ideas come directly from retailers or end customers, via trade fairs and other events or from the company’s own employees. All this leads to about 30 new products, either innovations or improvements on existing products, being launched on average each year.

The management is especially pleased to have received this recognition because it confirms the company’s path thus far, the work it has done, and its future direction all at once. König says, “We have been supporting musicians in their day-to-day lives with innovative products and ideas for decades now. We always observe our market very closely and respond early on to trends so we can stay competitive and be the first to bring new and groundbreaking innovations to market. A thriving corporate culture that actively promotes and supports ideas and suggestions for improvements from employees is a crucial part of this.”

TOP 100

The TOP 100 awards ceremony is scheduled to be held in Ludwigsburg, in the state of Baden-Württemberg, on November 26, 2021. König and Wolz hope they can both attend in person. If this is still impossible due to the pandemic, the organizers will have to demonstrate their innovative spirit.

König & Meyer receives innovation award with TOP 100 seal

König & Meyer has received the TOP 100 seal for the first time. This puts us in the ranks of particularly innovative medium-sized companies from all over Germany. Previously, we were subjected to a scientific test procedure in which the innovation climate was able to convince the jury.

For more than 25 years, the “TOP 100” seal has been awarded to mid-sized companies based in Germany in recognition of outstanding innovation management. Every year, one hundred innovative companies across three size categories receive the award. In this way, “hidden champions” are bundled together on a single platform across all industries, which enables them to gain considerable visibility. As mentor, science journalist Ranga Yogeshwar gives this only competition of its kind a well-known face.

Companies are evaluated based on 120 criteria in five categories: Successful Innovations, Climate of Innovation, Innovative Processes/Organization, Benchmarking/Open Innovation, and Innovation-friendly Senior Management. The basic question is whether innovation is the product of deliberate planning and action or of chance alone, meaning whether innovative achievements can be repeated. The competition also looks at whether the solutions involved succeed on the market, and if so, how. This time around, special attention was paid to how companies responded to the COVID-19 pandemic.

Especially in these kinds of crisis situations, it is even clearer what innovative drive can achieve. With all cultural life in lockdown, demand for event technology and music equipment plunged. In response, König & Meyer sought out new opportunities. Within just three weeks, the company came up with a whole new product line and launched various disinfectant stands on the market.

CEO Gabriela König

“Our philosophy of streamlined communications, our own high level of vertical integration, and the structured processes we use for product development really proved their value here. The strong demand for these products helped us all through 2020 to absorb the sharp drop in sales that we saw particularly in terms of products for events, especially live events. The disinfectant stand product range has now grown to more than 30 products,” says our CEO Gabriela König, describing the company’s internal flexibility.

Our company also received special recognition for its structured approach to innovation management and the good innovation climate within the organization.

CTO Heiko Wolz

“We have a clear approach that ensures that the necessary steps from the idea to market launch don’t have to be reconsidered every time, thanks to defined project management. Our portfolio is balanced and encompasses everything from short-term to long-term projects. Advances in product development are monitored and coordinated regularly. Every new product is reviewed and tested before it is launched on the market. We have innovation project teams composed of employees from various areas, who are continuously in touch, sharing information and ideas. Streamlined communications and flat hierarchies give us agility in implementing projects,” says CTO Heiko Wolz, offering insight into the company’s internal processes.

Everything comes togehter

Here at König & Meyer, expertise and creativity come together. We have our own design and development department and dedicated product managers who interface with the management and the technical departments and with the sales and marketing teams. Product ideas come directly from retailers or end customers, via trade fairs and other events or from the company’s own employees. All this leads to about 30 new products, either innovations or improvements on existing products, being launched on average each year.

Our management is especially pleased to have received this recognition because it confirms the company’s path thus far, the work it has done, and its future direction all at once. König says, “We have been supporting musicians in their day-to-day lives with innovative products and ideas for decades now. We always observe our market very closely and respond early on to trends so we can stay competitive and be the first to bring new and groundbreaking innovations to market. A thriving corporate culture that actively promotes and supports ideas and suggestions for improvements from employees is a crucial part of this.”

TOP 100

The TOP 100 awards ceremony is scheduled to be held in Ludwigsburg, in the state of Baden-Württemberg, on November 26, 2021. König and Wolz hope they can both attend in person. If this is still impossible due to the pandemic, the organizers will have to demonstrate their innovative spirit.

Bio-based plastics reduce environmental impact

König & Meyer has long done its part to protect the environment by manufacturing high-quality, highly durable products that are easy to take apart when they reach the end of their lifecycle, with individual parts being either recyclable or reusable. Now K&M is going one step beyond. To meet the increasingly stringent requirements that apply to environmental protection, König & Meyer is introducing various new sustainable products made from bio-based plastics.

Bio-based plastics are made from 50% to 100% renewable plant-based raw materials, such as cornstarch, cane or beet sugar, vegetable oils, and cellulose derived from cotton or wood. Using renewable raw materials helps conserve the world’s limited supply of petroleum and reduces CO2 emissions on average when compared to conventional petroleum-based raw materials. Bioplastics are an especially good option for long-lasting products in particular, ensuring a positive environmental impact. At the same time, these plastics are just as sturdy, durable, and recyclable as conventional plastics, although they are not compostable or biodegradable. If you ever need to dispose of the product you have purchased, please have it industrially recycled. Do not litter or place it in the compost.

Forward-looking business practices require responsible use of resources. Sustainably produced biological raw materials can help protect the climate and the environment and preserve biodiversity. Bio-based plastics are an important building block of this development, and they are undergoing continuous improvement and refinement. We monitor the current state of the art on an ongoing basis.

Bio-based plastics – questions and answers

Why is König & Meyer now using bio-based plastics?

Bio-based plastic is not a new invention, surprising as that may be. The first industrially produced plastic (1869) was a bioplastic – celluloid. It was not until later, in the early 20th century, that the first petroleum-based plastics like the ones we still use today were invented. These kinds of plastic were cheaper, so development shifted toward them from then on.

The world would have to wait until after 1980 for new innovations in bio-based plastics, driven mainly by changes in environmental awareness. Renewable raw materials and closed material cycles were major arguments for these plastics. Later, replacing petroleum as the main raw material became an important factor as oil prices rose and the finite supply of resources dwindled. Producing petroleum is also increasingly risky for the environment, involving processes such as fracking. The goal is to use bio-based plastics made from renewable raw materials to achieve all of the outstanding use characteristics familiar from petroleum-based plastics while also conserving finite resources on a sustainable basis.

Are there any disadvantages to the K&M products made from bio-based plastic?

No. The products we offer that are made with bio-based plastics have no disadvantages compared to products made from conventional petroleum-based plastic. This is because the bio-based plastics were specifically developed and adjusted for our applications, so they are just as sturdy and durable.

Why aren’t all of König & Meyer’s plastic products bio-based?

We use many different kinds of plastic. The shift to bio-based plastics requires extensive development work. Not all bio-based plastics have the properties we need for our products. We are currently working on other products made from bio-based plastics, which we will be adding to our product range over time.

Are products made from bio-based plastic biodegradable or compostable?

No. Not all bio-based plastics are automatically biodegradable or even compostable. Long-lasting products that are supposed to remain in use under all climatic conditions for years cannot be made biodegradable or compostable in the end using current technologies.

How should products made from bio-based plastics be disposed of?

If the products need to be disposed of at some point, please have them industrially recycled. In these processes, the bio-based plastic is either recycled or used to generate heat and energy. The CO2 naturally stored in the plant-based raw materials is then either released or CO2-neutral energy is generated.

Does the land cultivated to produce bio-based plastics compete with the land used to grow food?

Only 0.02 percent of all agricultural land worldwide is currently used to produce bio-based plastics. All of the petroleum-based plastics required around the world could theoretically be replaced by bio-based plastics today, and even then, the renewable raw materials needed to make them would only occupy ten percent of the acreage used to produce foods that end up being thrown away in our society.

In a growing market, however, it is definitely important to make sure that production of bio-based plastics does not compete with growing food, now or in the future. With this in mind, researchers are making huge efforts to use waste generated by the timber industry and agriculture, such as green cuttings and straw, as raw materials for producing bio-based plastics.

What are the harmful effects of growing renewable raw materials to produce plastics?

We view the use of fertilizers, pesticides, genetic engineering, and water to produce renewable raw materials through a critical lens. The goal for the future is also to ensure that the raw materials used to produce bio-based plastics come from sustainable agricultural production practices geared toward ecological criteria.

Why has König & Meyer been using recycled plastics for decades?

We have always recycled byproducts of our in-house plastic processing activities by regrinding them and feeding them back into the production cycle. We use between 15 and 20 tons of regranulate a year. This is plastic material that does not need to be produced again as new materials, so it conserves resources and energy.

Our bio-based products

zum Produkt

zum Produkt

zum Produkt

zum Produkt

zum Produkt

zum Produkt

zum Produkt

zum Produkt

zum Produkt

zum Produkt

zum Produkt

zum Produkt

zum Produkt

zum Produkt

zum Produkt

zum Produkt

zum Produkt

zum Produkt

Products for health protection– Made in Germany

Regular and thorough hand hygiene is essential to fight viral infections such as the current Covid-19 coronavirus disease and, of course, pathogens in general. Especially in highly frequented areas and places where many people come together, germs can be transmitted quickly. Disinfecting the hands is vital to protect yourself and others from infections. However, facilities for hand disinfection must also be available.

With the mobile disinfectant stands, disinfectant holders and other equipment from König & Meyer you can protect your customers, employees and visitors safely and sustainably from germs. We offer you different models, which are ideal for use in commercial premises with high visitor frequency, such as hospitals, doctors’ surgeries, retail shops, hotels, restaurants, schools, event locations or business premises for installation in entrance and waiting areas.

The disinfectant stands 80340, 80310 and 80315 and the disinfectant wall holder 80330 are in neutral white and suitable for the most common disinfectant bottles. The 80370 holder is also available in black and can be used as a table stand or wall mount.

For Euro dispensers we offer the disinfectant stand 80320 in white, the disinfectant column stand 80350 in black and the table stand 80360 in black or white in our range.

In addition, disinfectant bottles can be mounted directly on the stands for the Euro dispensers thanks to the 80396 holder.

The versatile tray 80380 can be mounted on our disinfectant stands or generally to tubes up to a diameter of 30 mm which can be used in many ways for facial or cleansing tissue papers, face masks or other hygiene products.

You can attach useful information for your visitors to the poster display stand 80395 as well as to the information board 80390. The board can be mounted easily on the disinfectant stand 80320 and the disinfectant column stand 80350.

All products are made in Germany. On request, the models can also be manufactured in other individual dimensions.

Health Protection

(E-Paper)

Health Protection

(E-Paper)

The K&M Wall and Ceiling Mount Concept

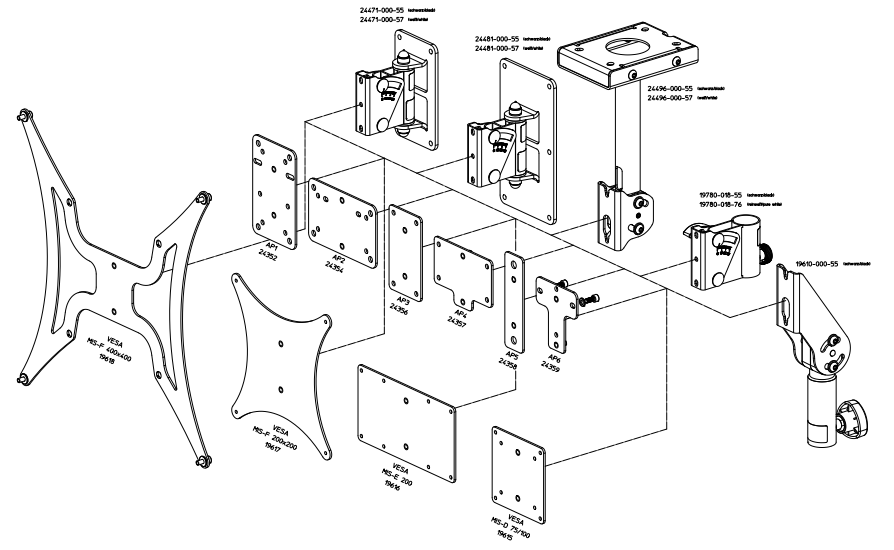

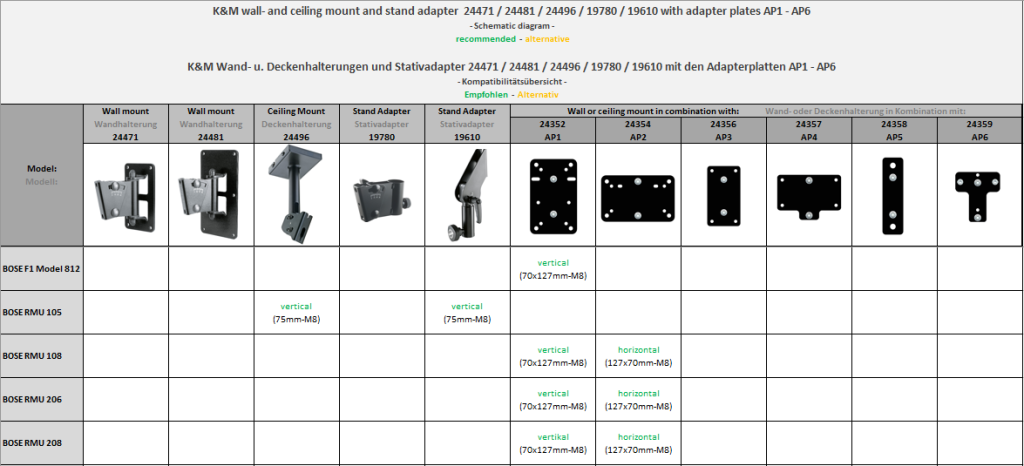

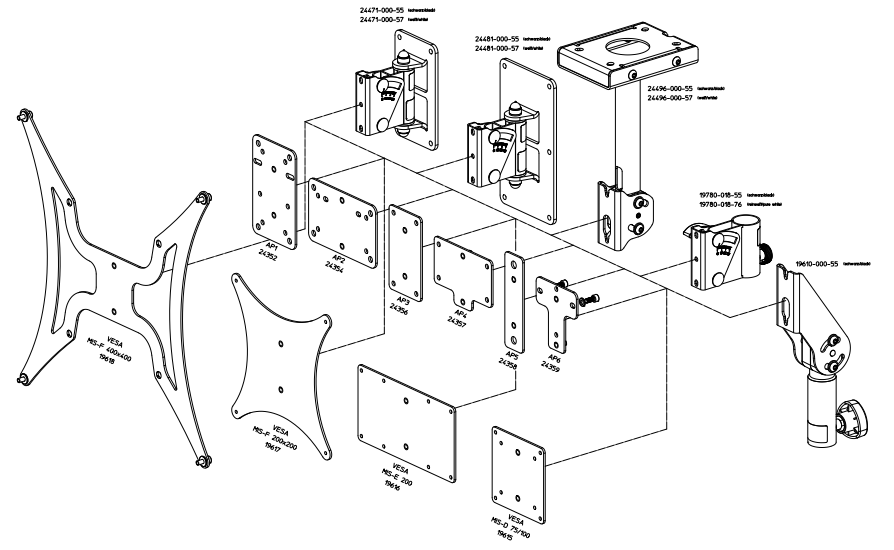

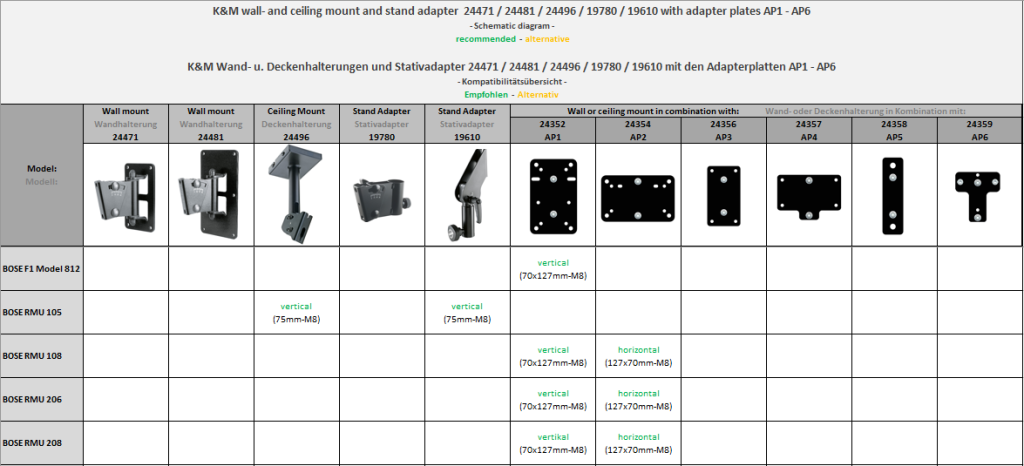

König & Meyer presents an innovative system of loudspeaker mounts, which consists of the following products:

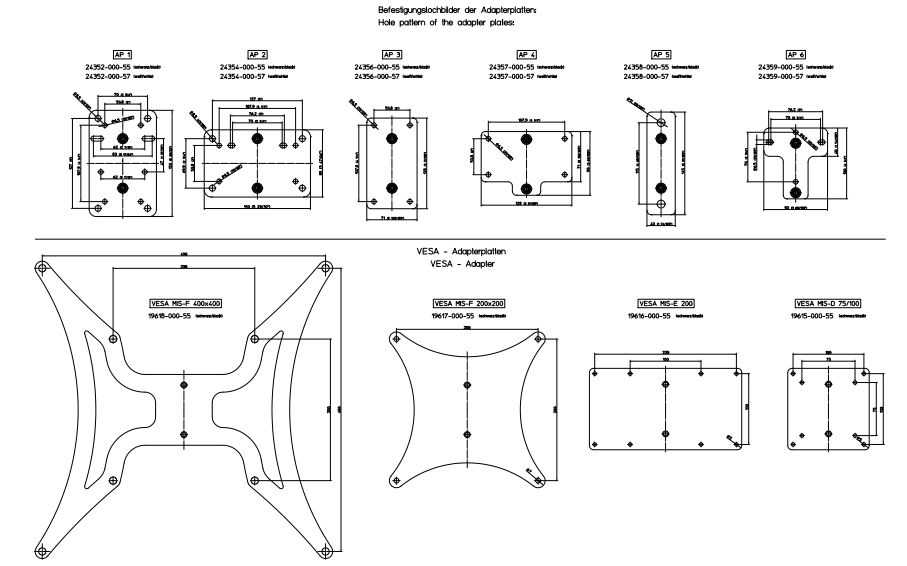

in combination with nine different adapter panels:

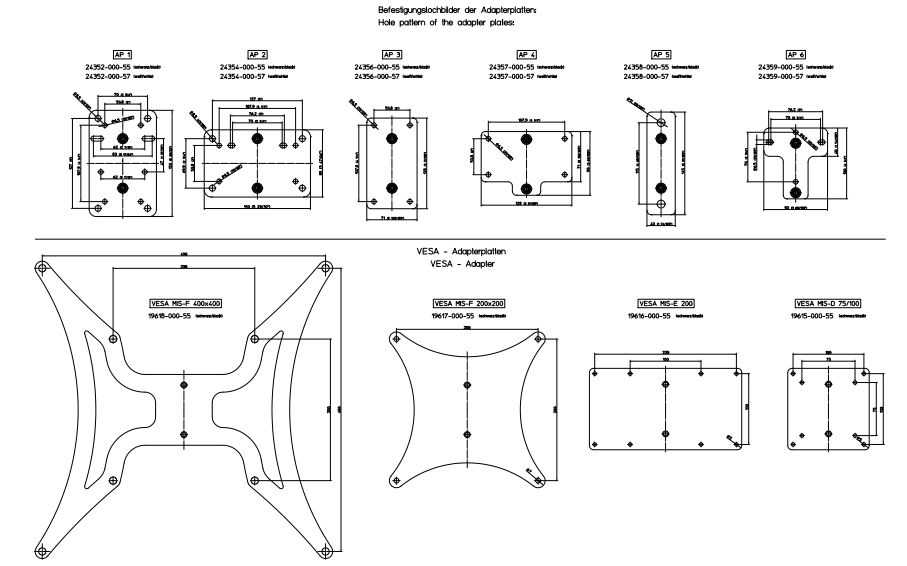

panel 1 24352 to panel 6 24359 as well as four VESA panels (19615, 19616, 19617, 19718)

The mounts are all functional, very robust and versatile. Thanks to variable angle and direction adjustments, the loudspeakers can be adjusted to your needs. The loudspeaker mounts can, depending on the requirement, be used with or without the nine adapter plates. The adapter panels have specific drill hole templates (to install on the loudspeakers), dimensions and vertical and horizontal mount for various loudspeakers.

The mounts are all functional, very robust and versatile. Thanks to variable angle and direction adjustments, the loudspeakers can be adjusted to your needs. The loudspeaker mounts can, depending on the requirement, be used with or without the nine adapter plates. The adapter panels have specific drill hole templates (to install on the loudspeakers), dimensions and vertical and horizontal mount for various loudspeakers.

This chart illustrates the five mounts, adapter panels and drill hole templates. In addition, the loudspeaker models of individual manufacturers are listed. This provides dimension and mount plus panel direction information for the various loudspeakers.

At this point in time, the list is up-to-date, however we make no claims to the completeness of the list, due to the fact that the loudspeaker industry does not adhere to any standards in this regard, but does offer a wide variety of individual solutions. But, in general, users know which drill hole template and adapter panel is needed for their loudspeakers. The exact drill hole templates for the adapter panel are provided in this Illustration.

This systems provides great advantages specifically in regard to installation, the system can be installed by one individual quickly and easily.

This systems provides great advantages specifically in regard to installation, the system can be installed by one individual quickly and easily.

First the plate from the wall mount 24471 and 24481 as well as the Inclinable stand adapter 19780 is mounted separately. Then the swivel support arm, which has already been removed from the mount, is attached to the loudspeaker using the corresponding adapter panel. Then, this combination can simply be attached to the wall mount. Finally, the whole system is secured with a locking screw.

Similar to the wall mount, the Ceiling Mount 24496 as well as the Adapter 19610 is separated from the plate. Then it is screwed into the loudspeaker with or without an adapter panel. An additional feature of the mount is the internal cable management. This allows for surface or sub-surface cable installations.

All mounts and adapter panels are available in both black and white; installation material and screws are not included. With the exception of AP6, which includes loudspeaker installation screws.

Video 1: König & Meyer Speaker wall mount concept

Video 2: König & Meyer Speaker ceiling mount Concept

Even in difficult times we are here for you!

The current development of the COVID-19 pandemic presents us with unprecedented challenges. Reducing or slowing down the spread of the coronavirus is a top priority worldwide.

We have implemented various measures within the company to ensure the safety of our employees and fellow human beings, minimize disruptions to our supply chain and support our customers across the board. Wherever possible, we work from our home office and can be reached via all media. We have also converted our production and distribution center to a strictly separated shift system. We have introduced additional hygiene measures for everyone whose presence is required in the company. This enables us to keep our company running without losing sight of the safety and health of our employees.

We would also like to assure you that we can continue to offer you the reliable service you are used to including an excellent availability of our products from stock.

Support the music trade, musicians and artists worldwide now:

Our trading partners need stability and support right now to continue to have a perspective. Some music shops now offer special services such as “contactless delivery” and special promotions. Look for them on the social media channels and music store websites. They look forward to your online visit.

We are convinced: Together we will survive this crisis. Stay safe and take care of your loved ones.

Sincerely,

Gabriela König

CEO

Join us for the next NAMM Show in Anaheim

The music industry from around the globe gathers in Anaheim again for the next NAMM Show from January 16 to 19, 2020. We look very much forward to your visit at our booth 14516 in the Anaheim Convention Center ACC North (Level 1). König & Meyer will be presenting new innovative products as well as tried and tested products. On our exhibition space in the Pro Audio Hall, you will learn about the trends for 2020. Do not miss this great event in Anaheim.

NAMM, the National Association of Music Merchants (NAMM), established in 1901, is the not-for-profit association that strengthens the $17 billion global music, sound and event technology products industry. The association and the NAMM shows serve as the crossroads for professionals wanting to seek out the innovations in music, recording technology, sound, stage and lighting products. Held in Anaheim every January, The NAMM Show offers the latest products from more than 7,000 brands, cutting edge industry education across hundreds of sessions, as well as special events, concerts and experiences where often “only at NAMM” moments take place. More information at www.namm.org

NAMM Show Hours

Thursday, Friday, Saturday: 10 a.m. – 6 p.m.

Sunday: 10 a.m. – 5 p.m.

Address:

Anaheim Convention Center

800 West Katella Avenue

Anaheim, CA 92802

Nitro lacquer info sheet

Our guitar stands in the translucent version are suitable for all kinds of guitar lacquers, including nitro lacquer. The colorless support elements are made of high quality elastomer plastic, which does not contain any color.

Therefore discoloration from the stand to the guitar is eliminated. However with nitro lacquers which are not fully hardened it can happen in some cases that the colors of the guitars “bleed”, that means that the colors blur or fade, and can cause dents.

König & Meyer is not liable for such damages!

Please regard the respective guitar manufacturer’s instruction manual.

We recommend to keep high quality guitars in the guitar case for long-term storage.

Relevant for:

16280-014-00 Guitar wall mount

17513-016-00 Three guitar stand »Guardian 3«

17515-016-00 Five guitar stand »Guardian 5«

17525-016-00 Five e-guitar stand »Guardian 5«

17534-016-00 Four guitar stand »Guardian 3+1«

17540-013-00 E-guitar stand

17605-000-00 Four guitar stand »Roadie«

Click here to open the info sheet (pdf).

The mounts are all functional, very robust and versatile. Thanks to variable angle and direction adjustments, the loudspeakers can be adjusted to your needs. The loudspeaker mounts can, depending on the requirement, be used with or without the nine adapter plates. The adapter panels have specific drill hole templates (to install on the loudspeakers), dimensions and vertical and horizontal mount for various loudspeakers.

The mounts are all functional, very robust and versatile. Thanks to variable angle and direction adjustments, the loudspeakers can be adjusted to your needs. The loudspeaker mounts can, depending on the requirement, be used with or without the nine adapter plates. The adapter panels have specific drill hole templates (to install on the loudspeakers), dimensions and vertical and horizontal mount for various loudspeakers.

This systems provides great advantages specifically in regard to installation, the system can be installed by one individual quickly and easily.

This systems provides great advantages specifically in regard to installation, the system can be installed by one individual quickly and easily.